Gas turbine & Power Generation Component Testing

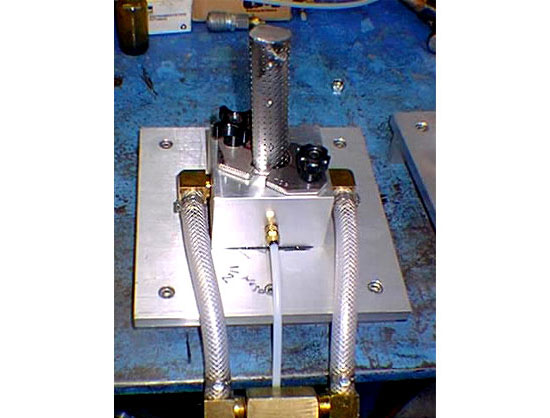

CCDI creates custom airflow fixtures for turbine parts and components, enabling our customers to perform tests with any EFA or mass airflow machines. Our Engineering department will require you to send us your drawing / part or we will accept 3D data in STEP (.stp) or IGES (.igs) format. All fixtures are built to specifications from our cutomers. CCDI will insure your fixtures are built with the correct plenum sizing, diffuser screen, pressure tap positioning and bell mouth curved inlets to spec, guranteed.

Simply provide us with the part drawing which contains the airflow requirements and we'll take it from there!

CCDI is your one stop airflow company. Contact us to let us know your challenge or problem; and we'll deliver you a solution.

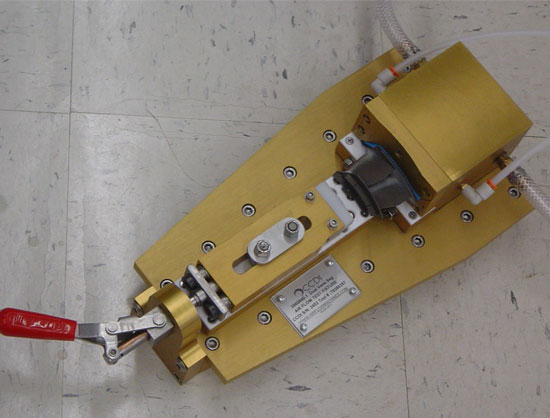

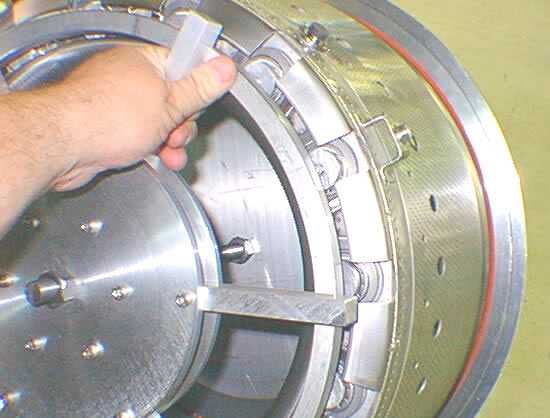

Effective Flow Area (EFA) Aero Dynamic Test fixtures

CCDI has designed and manufacture the lowest turbulent airflow fixtures in the world. Our EFA fixtures all have bell mouth inlets smoothing the airflow directly into the vane flow areas providing the most accurate EFA tests.

Pratt and Whitney Canada PT6, Honeywell (multiple engines) and Rolls Royce combustersCustom Fixtures:

- Airflow Test Fixtures for Vane Segments

- Airflow Test Fixtures for turbine engine blades and vanes

- Airflow Test Fixtures for combustors

- Built for Mass Airflow testing of any turbine blade, vane, or shroud for ALL engines by Specification

- May be pneumatically operated to increase productivity

- Custom molded gaskets and o-rings

- Single hole to multi airflow testing capability

- Send us your engine component or airflow requirements and we'll be pleased to provide you with a competitive quote. If we do not have the part in house, we may request for you to send it to us to ensure perfection the first time around.

- 2D and 3D Fixture drawings are also available for additional costs.

Past fixtures we've created:

GE

- GE Energy - 7H Stage 3 Nozzle

- GE Energy - 201E3510 Inner Segment Shroud

- GE Energy - 9H Stage 3 Syngas Nozzle

- GE Energy - 7H Stage 2 Nozzle

- GE Energy - 7FB Stage 1 Nozzle

- GE Energy - 9FB Stage 1 Nozzle

- GE Energy - 7FA Stage 1 Vane

- GE Energy - 7FB Stage 1 Shroud

- GE Aviation - 2254M3500 Inner/Outer Liners

- GE Aviation - 112E5180 Stage 2 Impingement Liner

- GE Energy - 9FA 119E1560 Impingement Plate

- GE Energy - 7FA 115E6073 Impingement Plate

- GE Energy - 6FA Stage 2 Bucket

- GE Energy - 7E Stage 1 Bucket

- GE Energy - 7FA Plus Enhanced Stage 2 Bucket

- GE Energy - 7FA Plus Enhanced Stage 1 Bucket

- GE Energy - 9E Stage 1 Bucket

- GE Energy - 9E Stage 2 Bucket

- GE Aviation - Nacelle Leakage Detector

CFM

- (All components)

Honeywell

- 3060840 - 1 Dual Vane Segment

- 3091795 - 2 Dual Vane Segement

Rolls Royce

- Rolls Royce - 501K Dual Vane Segment

- Rolls Royce - 05-23075776 Combustor

- Rolls Royce - T56-501 Stage 1

- Rolls Royce - 250 - Diffusers (All)

P&W

- P&W - F100

- P&W Canada - PT6 Rotor Vane Ring

- P&W Canada - PT6 Stator

Siemens

- Siemens - V94.2 Stage 1 Blade Water Pressure