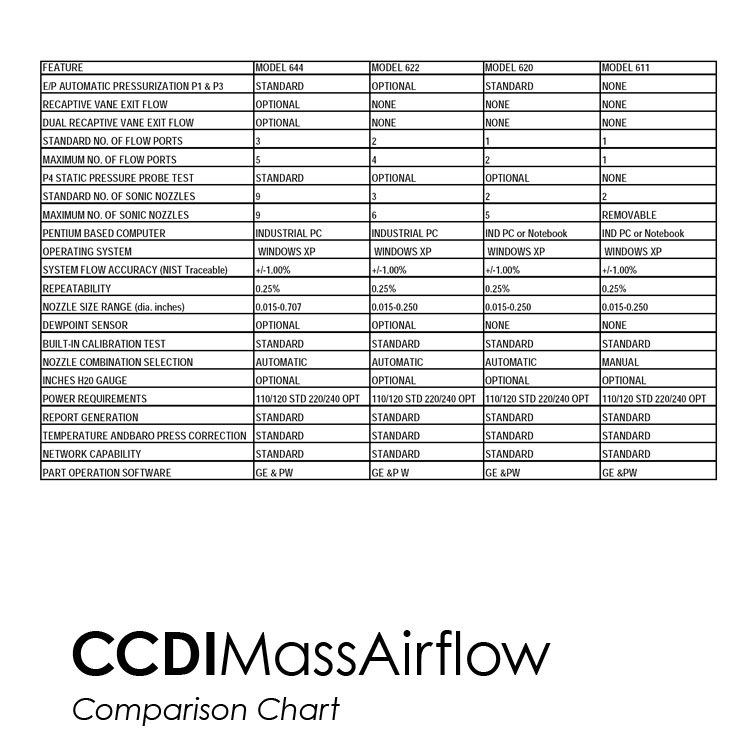

Our airflow test stands were the first in the industry to offer test equations for multiple manufacturers. Flow test sequences, called "circuits" can automatically flow air with multiple test steps and with various airflow equations (i.e. specialized reduced airflow measurements)

Ideal for testing cooling holes of Turbine Engine Blades, Vanes, Shrouds, Combustors, Nozzles, and Buckets.

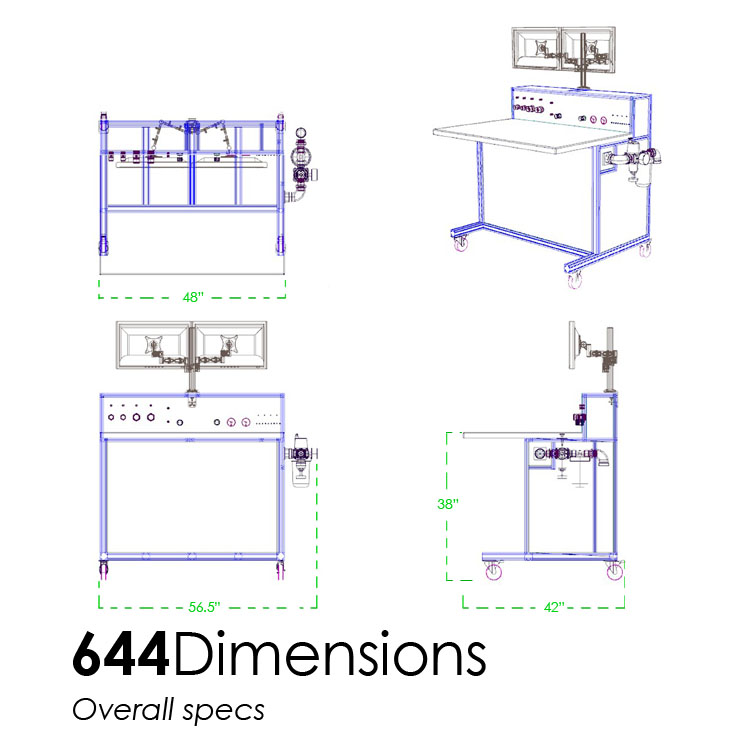

Model 644 Automated Airflow Test Stand Low, Medium, High, XH Configuration

Flow Capabilities

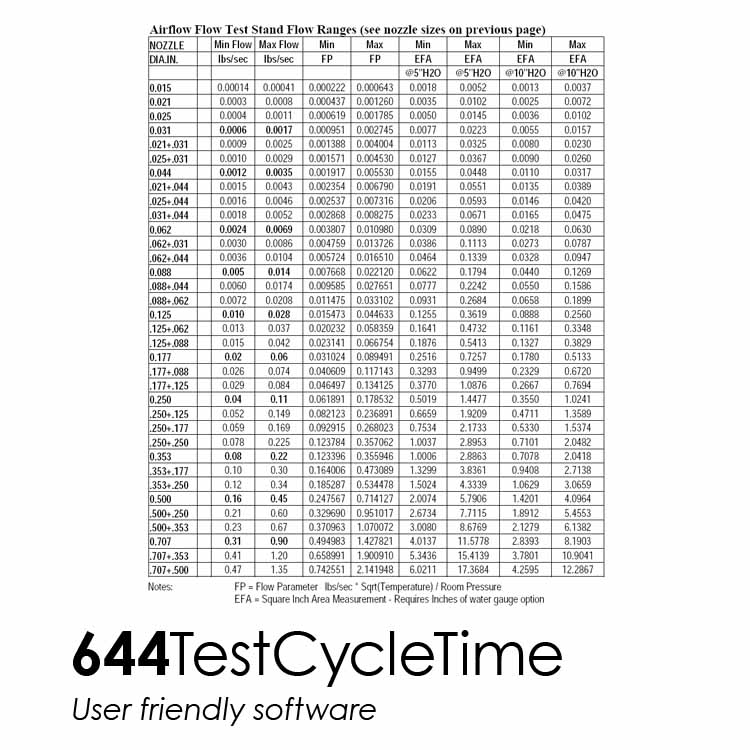

- 0.000119 to 1.231 Pounds per Second

- 0.000189 to 1.956 Flow Parameter

Specifications

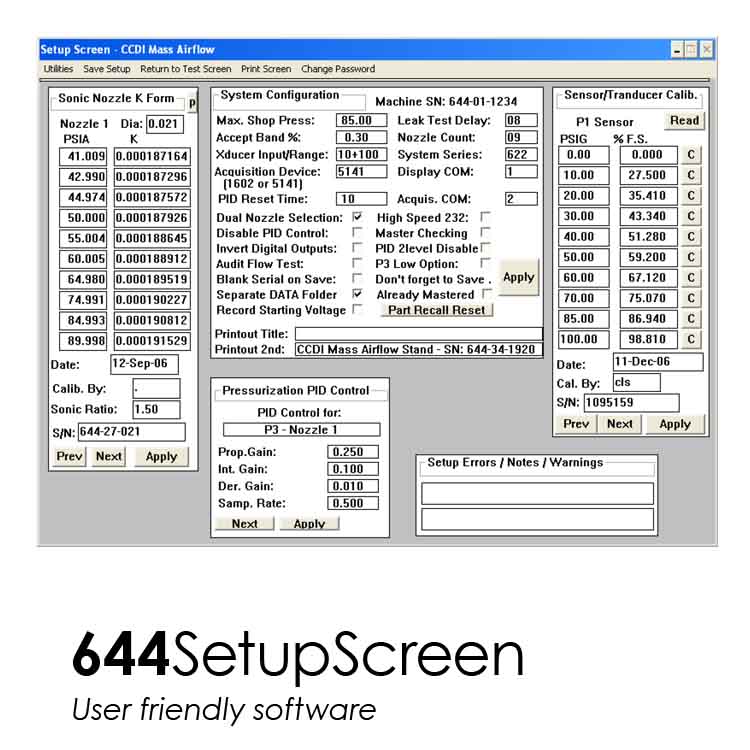

- Automatic Operation, Pressure Control and Switching

- NIST Traceable Airflow Measurement

- High accuracy Mass flow measurement with uncertainties of up to 0.20%, with option to improve uncertainty to 0.16% using premium precision sensors

- ANSI/NCSL-Z540 Calibration

- GE, Pratt & Whitney, Honeywell, ABB, Rolls-Royce, Siemens

- 15 to 45 Seconds per Part Test

- Fully Automatic Operation and Pressurization

- Sonic Nozzles (9) – with Automatic Size Selection

- Single or Dual Sonic Flow Nozzle Operation

- Part Test Profiles Available for Hundreds of Engine Parts

- English and SI Units

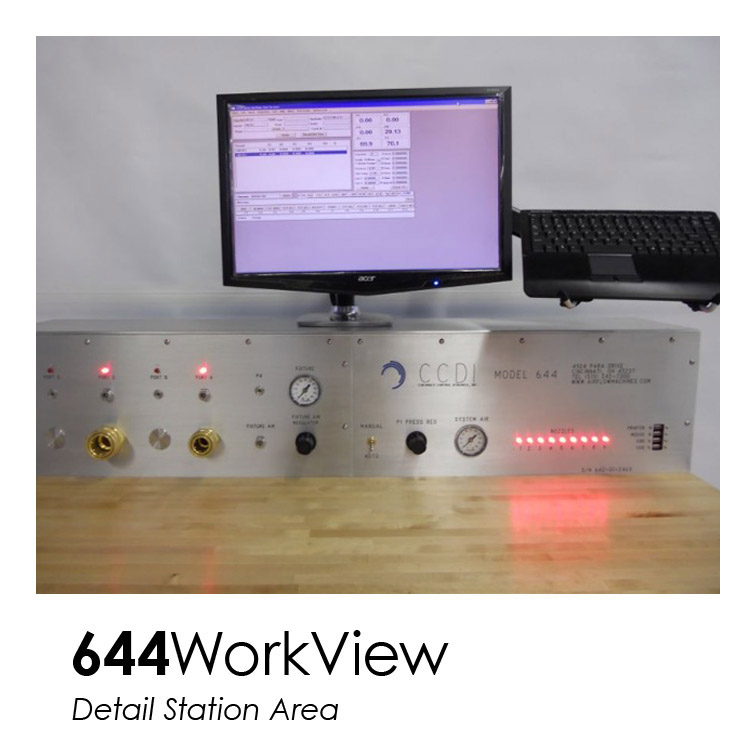

- Industrial Intel Computer

- Dual LED displays on ergonomically friendly Ergotron arms

- Quality Control Report, Label and Data Acquisition File

- Included In-house or Online Operator Training, Testing and Certification

- Included One Year Warranty on Parts and Labor

- Can also flow small Effective Flow Area measurements

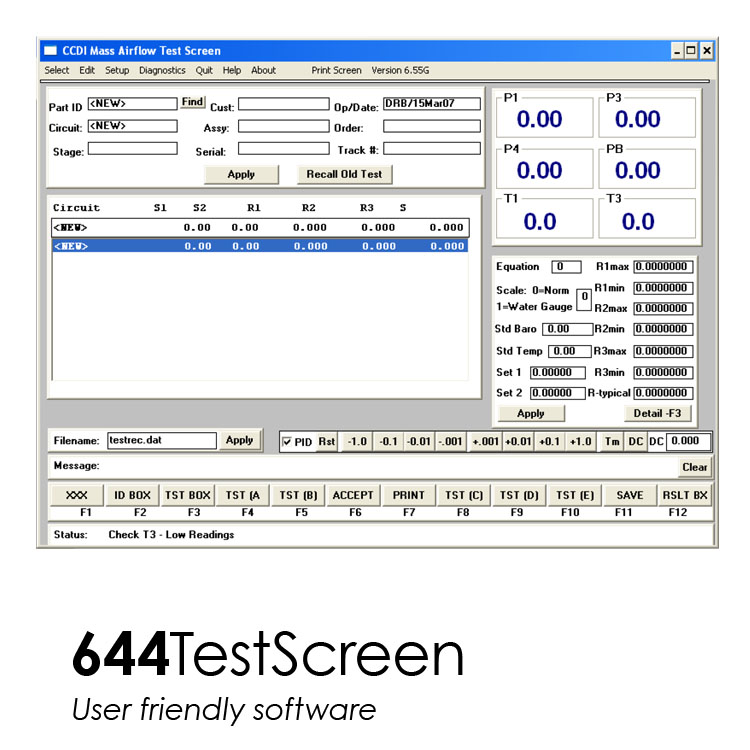

- Real production oriented software designed for Airflow Measurement

- Machine weight 512 lbs.

Options

- Additional Flow Ports B & E

- Low Pressure P3 0-2 PSIG (0-55 "H2O)

- Bar Code Reader

- Label Printer and Bar Code Software Output

- Printer

- Enhanced Report Software (8.5 x 11 or A4)

- Wireless Network Option

- Dew point Meter w/Warning

- Data Conversion

- Low Pressure Warning

- Lockout Box

- Side Table (Left or Right)

- Statistical Software

- Networked Results Server

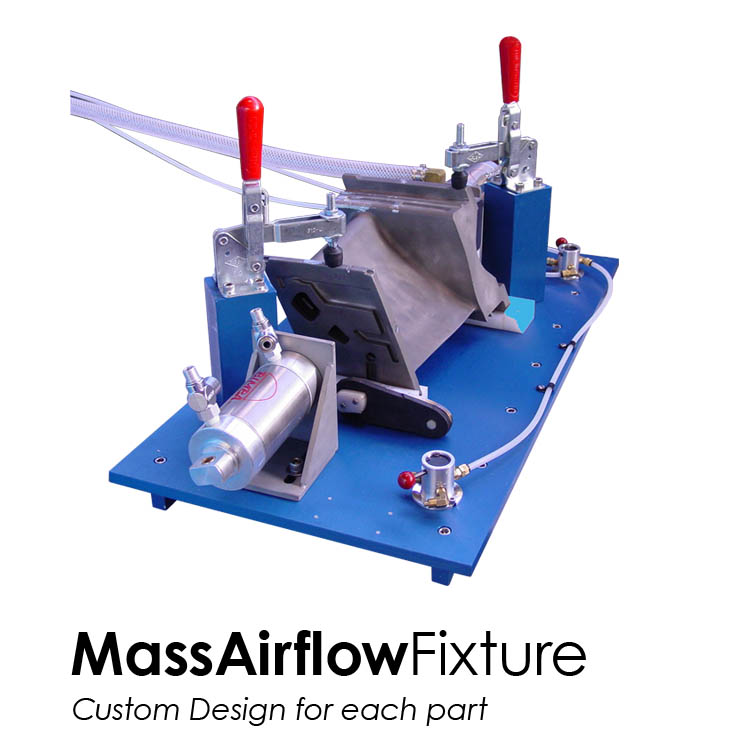

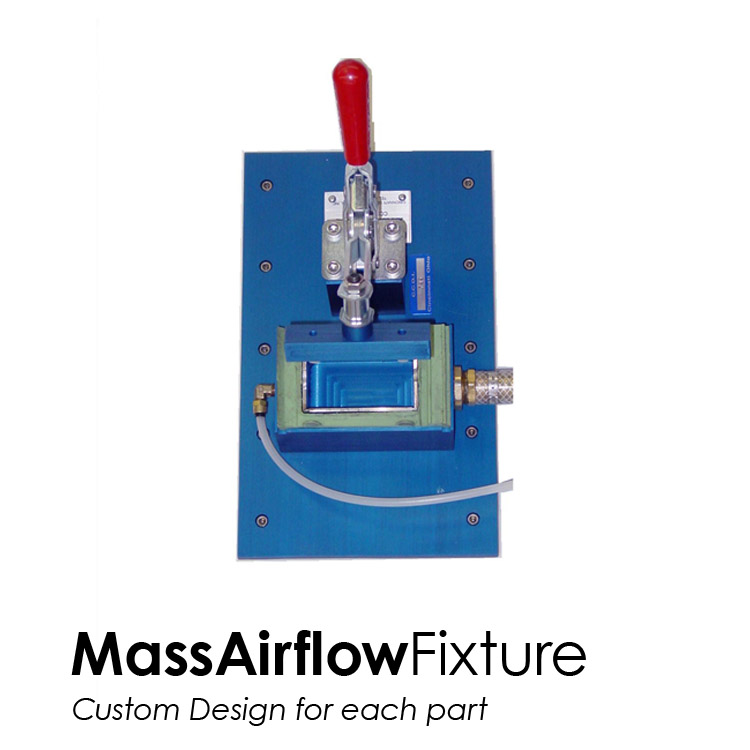

- Fixture Control Language, Send Commands to Tooling

- Inset LCD Display (Instead of external mount)

- External Verification Master Nozzles

- Air Dryer Systems

- 300 - 500 Gal. Accumulator tanks sold in pairs

- Lifetime annual calibration packages

Disclaimer - Standard measurement uncertainty is up to 0.50% without lab calibrated nozzles. Measurement uncertainty may vary with flow, sensors used, calibration etc. Contact CCDI engineering to ensure best case uncertainty can be achieved for your test setup